Experiencing the Avion A320 Simulator

On the 19th of July I was offered to try out the Avion A320 NEO full flight motion simulator, by David Davidson.

David is a tug pilot at the club. As a thank you for CGC’s help in hosting his company and flight simulator engineers for a day at the gliding club, David freed up a simulator slot on Friday the 21st of July between 7 and 10AM. The simulator runs 24/7 and is booked every day apart from 25 Dec and 1st Jan, so this was a very special opportunity!

The Avion A320 Full Flight Simulator (FFS) is a level D simulator built by Avion; it is basically the closest you can get to the real thing. As they form part of a pilot’s training and certification procedure, they are closely regulated by aviation regulators. The United States Federal Aviation Administration (FAA) and the United Kingdom Civil Aviation Authority (CAA) both use the same terminology and classification for full flight simulators, with four levels of increasing sophistication (A to D, with D being the highest).

Ahead of the flights on Friday, David sent us a few links to consult, so that we could limit to a minimum the briefing time and spend more time flying in the simulator. One notable difference between flying a glider and a commercial aircraft (apart from having engines or weighing 150 thousand times more) is the Fly-By-Wire (FBW) system.

With the Fly-By-Wire (FBW) system, the movements of flight controls (e.g., stick and rudder) are converted to electronic signals transmitted by wires, and then converted into mechanical motion by hydraulic actuators at the control surfaces (e.g., ailerons, elevator, tailplane). Between the flight controls and actuators, the signal passes through a series of flight computers. These flight computers interpret the pilot’s control inputs as a desired outcome and calculate the control surface positions required to achieve that outcome most efficiently. FBW has several advantages, such as weight saving (stability surfaces such as fin and tailplane can be made smaller, because the flight computer can stabilize the aircraft with microseconds adjustments); improved efficiency of flying (coordinated turns, straight-line flying); increased safety (increased redundancies, reduced workload for pilots, improved handling, prevents the plane to be flown outside the flight envelope); and maintenance reduction. For example, to initiate a right turn in a FBW system, it is sufficient to move the stick to the right, without the need to apply any right rudder, as one would do in a traditional aircraft. Once the desired angle of bank has been reached, the stick can then be centralised again and the plane maintains a constant rate of turning, while keeping the speed and altitude constant. Instead, in a glider, one would ease the stick back and slightly left to keep the glider in the right turn.

Our slot on the simulator was booked at 7am at Luton Airport, so I woke up at 5am and started cycling to Paul Ruskin’s house, who very kindly offered me a lift. In the car, we listened to BBC’s radio sitcom Cabin Pressure, which I strongly recommend!

We arrived at Luton at 6:40am, the hangar had a large Avion sign written on it, so we couldn’t have missed it (we actually did and had to turn around). We parked at the front of the building and rang the door. An Avion engineer welcomed us inside. Having signed our life away, we were shown around the building.

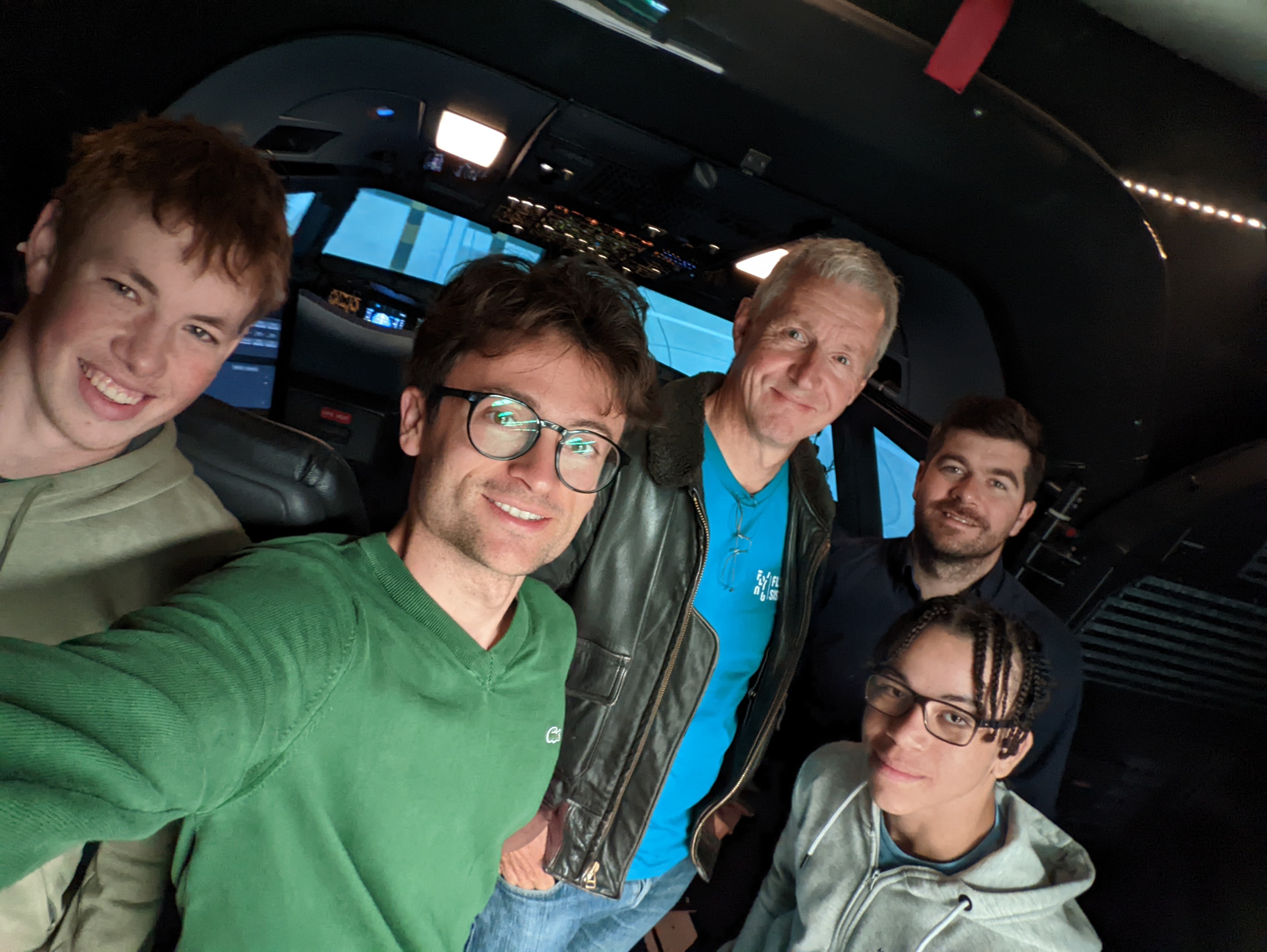

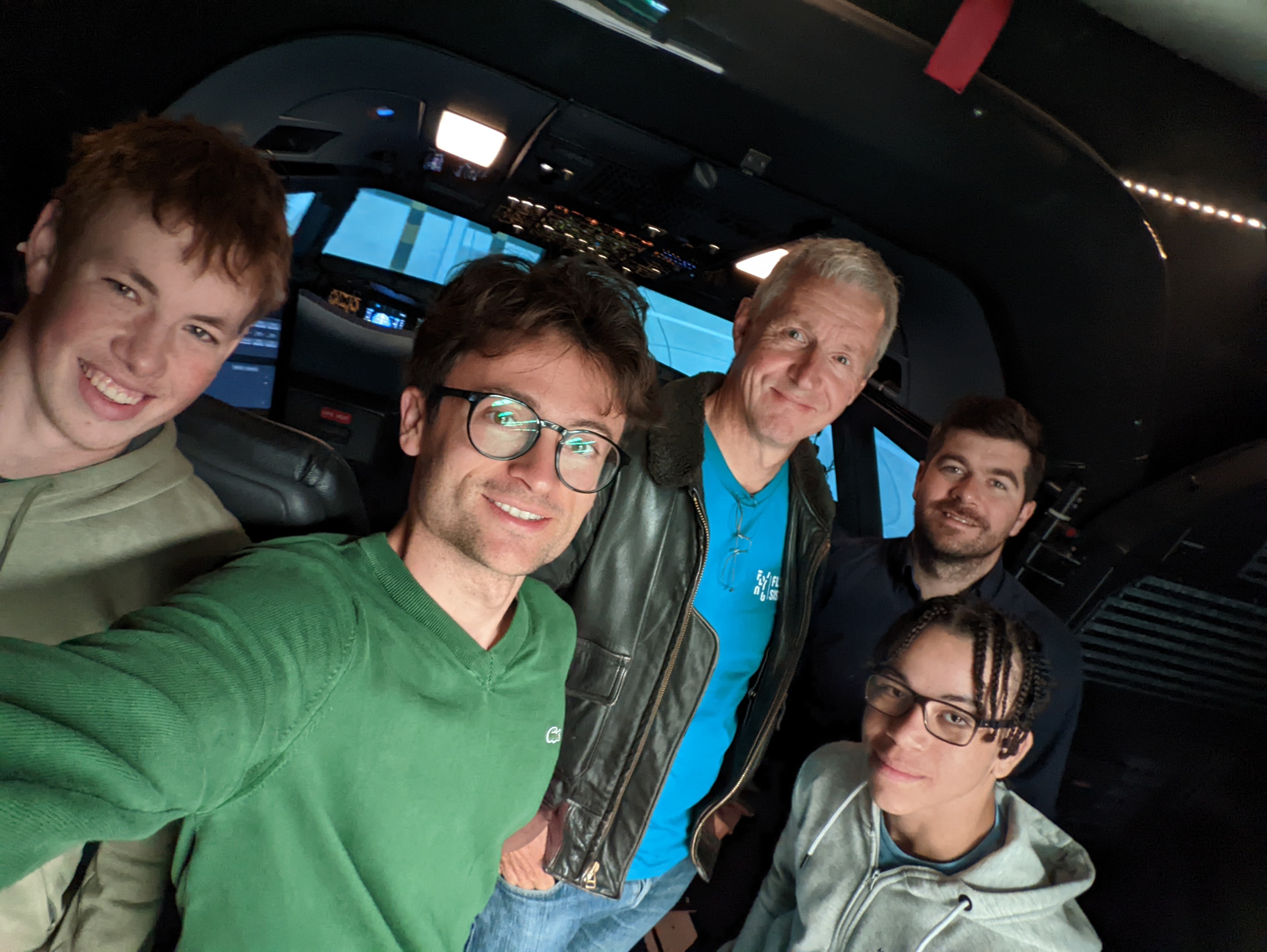

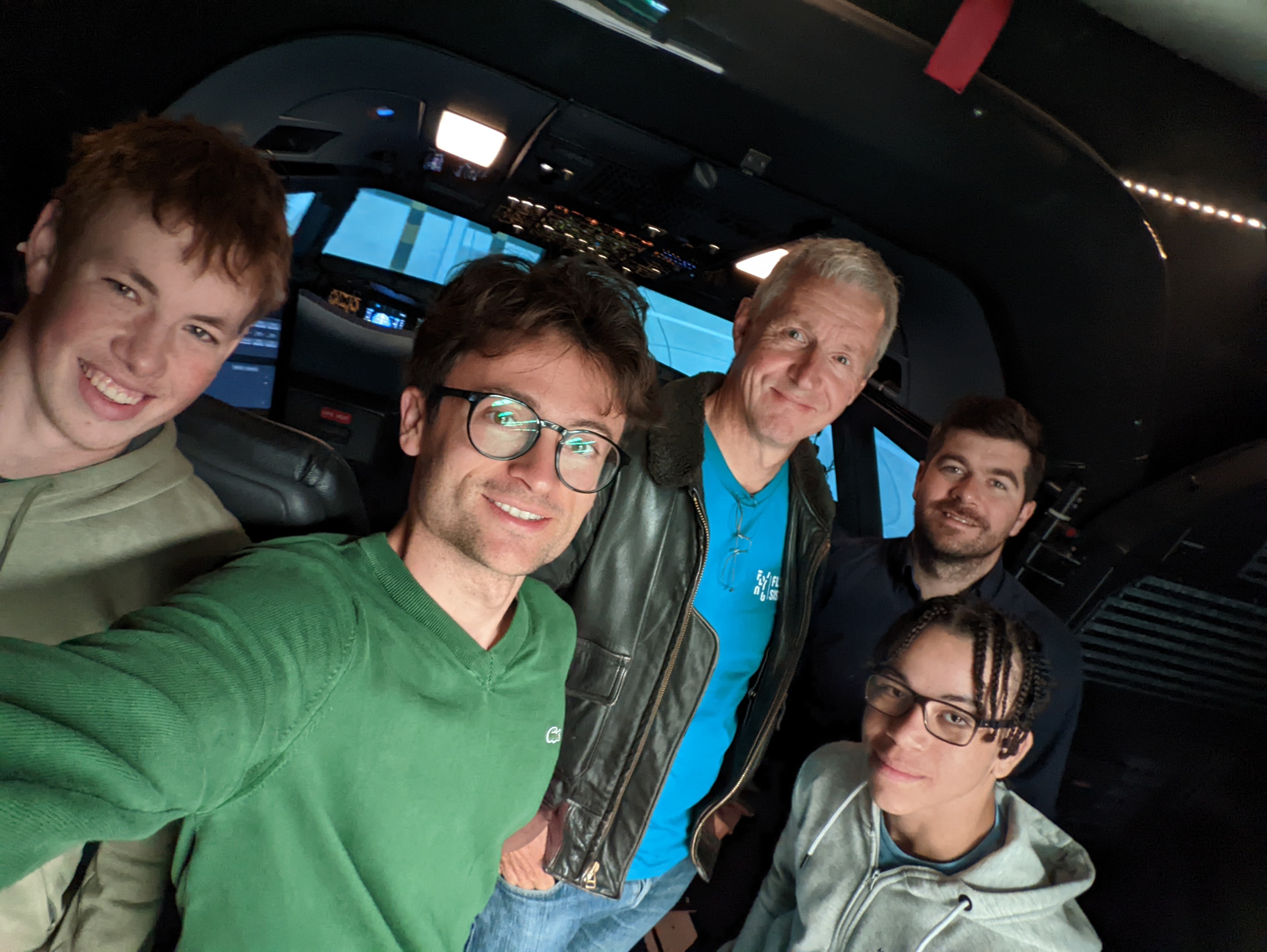

The facility was a large warehouse, with the Avion simulator at the opposite end. On the side we entered from, there were a few briefing rooms, where airline pilots would be briefed two hours before their flight in the simulator. We then walked up the stairs above the briefing rooms to a lounge overlooking the simulator. Coffee, tea and biscuits were free, and we immediately took up on the offer. Later, Erik and Ryan, the other two guests, also arrived. Finally, David joined us and we started the briefing. Erik and Ryan went first. Paul and I watched them from the lounge, where a screen recorded their flight in the simulator.

After about an hour and a half, the 7-tonne simulator, which had been shaking vigorously a few seconds earlier from side to side, came to a halt and a ladder extended from its side, lowering to the ground. Erik and Ryan got off, their faces full of excitement. They didn’t tell us then, but their last flight contained a very unexpected surprise, which we would later also experience! It was time for Paul and I to get inside.

Inside the simulator, I took the instructor’s back seat, David was in the captain seat and Paul sat in the co-pilot seat.

Firstly, David took off, flew us around, and demonstrated the basics of flying with and without the autopilot. He showed us how to plan the circuit, using the Navigation Display (ND) as a reference and explained the landing technique, focusing on the Primary Flight Display (PDF). On final approach, the Instrument Landing System (ILS) provides information on the vertical and horizontal position of the aircraft with respect to the runway. Data from the ILS is then displayed onto the PDF as two purple diamonds on the horizontal and vertical deviation scales. Then, the pilot attempts to manoeuvre the aircraft to keep the indicators centred while they approach the runway to the decision height of 200ft.

On a FBW system, as the nose is lowered to keep the vertical diamond centred, the thrust is adjust automatically, to keep the aircraft at the correct speed for that flap setting. Closer to the runway, the pilot can further verify they are on the right slope to the landing area by looking at the VASI lights (Visual Approach Slope Indicator). These are a total of 4 lights to the left side of the runway. If the height is exactly right, then one sees 2 white and 2 red lights. If too low, the number of red lights increases, if too high, more white lights than red lights are visible.

The first flight went relatively smooth. Next, we tried an engine failure and subsequent landing. This required trimming the rudder to one side, a kind of trim we don’t have on a glider!

Next it was my turn in the co-pilot seat. I started by trying out a standard take-off and landing. After that, we loaded a more challenging scenario, landing with a 50knt cross wind. This required a lot of crabbing and full rudder just before touchdown, just like in a glider. After that, we turned off the fly-by-wire system and experimented with the plane’s flight envelope. We stalled the Airbus A320, at which point we could really feel the whole cabin shaking intensively.

Finally came the big surprise that would explain Erik and Ryan’s big smiley faces: David recreated for us the Hudson Landing: double engine failure shortly after take off due to a bird strike. The only option was to land out in the Hudson! This wasn’t a problem for glider pilots like us.

Flying at the best glide speed of about 220knts, we only had 2000ft when I initiated a sharp left turn, 30 seconds after the double engine failure (to account for checklist engine restart and exploring other landing options). Now flying at right angles to the Hudson, I waited until I crossed the river bank closer to us before turning final, at about 800ft. Once established on final, I gradually lowered the flaps to FULL and eased back on the stick to decrease the speed, from best glide (220knts) to min sink (140 knts). At 50ft, we hear the countdown 50, 40, 30, 20, RETARD, RETARD, 10, 5 … and the whole cabin shakes violently as we land in water. But we survive!

Thank you again to David for this unforgettable experience.

Flavio Salvati

2023-24 CUGC President and Equipment Officer